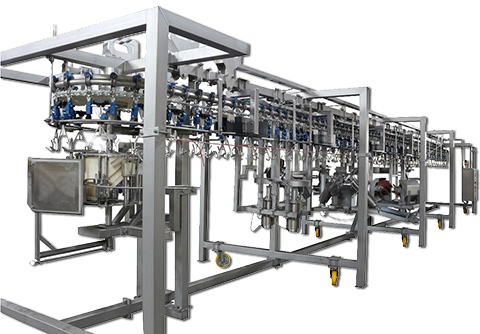

Compact Cut-up System

The Compact cut-up system is designed for efficient and economic operation of cutting plants.

It is designed as modular unit, which allows the installation of several different units according to clients requirements to perform every cut / product which is requested by the market.

It is designed as modular unit, which allows the installation of several different units according to clients requirements to perform every cut / product which is requested by the market.

All modules are supplied with a water connection in order to enable a continuous blade cleaning during the operation if desired.

The plant capacity is up to 6,000 birds per hour.

Birds within a weight range from 1,000 to 2,400 Grams eviscerated bird weight can be processed, separated into 3 different weight classes.

Available modules:

Click on a module (below) to learn more...

- Wing

Cutter

- Tail

Cutter

- Breast Cap

Cutter

- Breast

Pre-Cutter

- Front Half

Cutter

- Leg

Cutter

- Thigh

Cutter

- Drum

Unloader

| Raw product | Aged or fresh products |

| Capacity | 6,000 birds per hour |

| Weight grades | 1.10 – 1.50 kg |

| 1.50 – 1.90 kg | |

| 1.90 – 2.40 kg | |

| Other weight grades upon request | |

| Power consumption | Depending on modules |

| Power supply | 400 V – 50 Hz |

| Water connection | ½" |

| Water consumption | Depending on modules |

| Required staff | 1-2 for bird hanging |

| Dimensions: | Basic length 8.600 mm |

| Width 1.300 mm | |

| Height 2.067 mm |