PLUG & PLAY POULTRY PROCESSING LINES

Our "Plug & Play" poultry processing lines are designed for capacities from 500 up to 1,000 chickens per hour. This proven equipment is mounted on a steel frame (galvanised or stainless steel, based on your preference) and shipped fully assembled in a standard 40-foot container, ready for immediate use inside your factory building. Each line includes a live bird hang-on area, a water bath stunner with a high-frequency control unit, a bleeding trough, a scalding tank with jacuzzi-style water agitation, a defeathering machine (either four-bank with 32 disks or six-bank with 48 disks, depending on bird size) with a feather-catching tray, a head puller, an evisceration trough with water taps, a pneumatic neck and foot cutter, and an electrical control box.

The system arrives pre-wired and nearly operational, eliminating the need for costly on-site installation by our engineers. You’ll need to connect a 3-phase power supply to the control cabinet, water to select machines, and a small compressor for the neck and foot cutter. The assembled line fits within a standard 40-foot shipping container, which must be unloaded before operation.

We offer three line sizes: a 500-chicken-per-hour model, a 700-per-hour model, and a 1,000-per-hour model. Additionally, we provide a combination line suitable for broiler chickens, female-sized turkeys, and ducks, as well as a dedicated "Plug & Play" waxing line for ducks. The base 500-per-hour line starts at €125,000 (excluding shipping to your nearest seaport) and includes a galvanised steel frame and a four-bank, 32-disk defeathering machine. Optional upgrades include a stainless steel frame for an additional €8,500 and a six-bank, 48-disk defeathering machine for larger birds, also €8,500.

Post-evisceration chilling solutions must be considered. Depending on daily volume, you can use 1-meter-square plastic bins with ice water or opt for a 1.6 x 3-meter spin chiller (see our pre-chill equipment).

Note: The cost of the shipping container and delivery from your nearest seaport to your location is not included in the price.

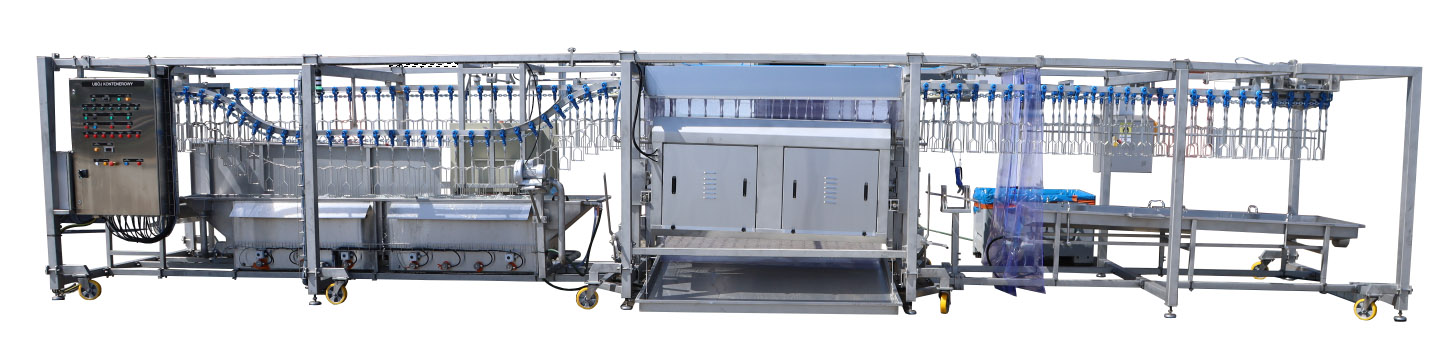

Photo of the entire processing line structure.

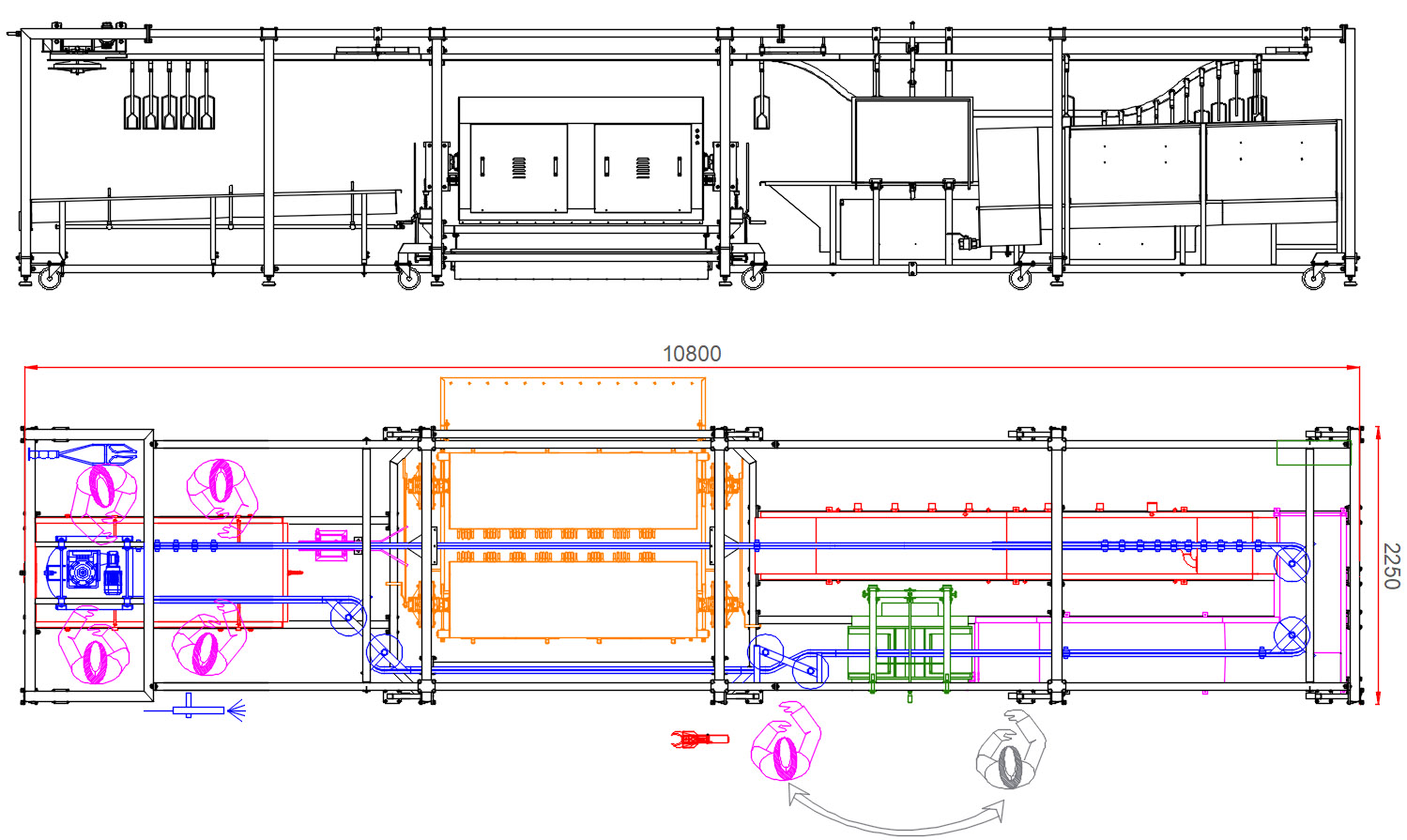

Elevation and plan of the main processing line structure.