Automatic Carousel Cut Up Line

Type: ADK

The Carousel cut-up line has a capacity of up to 2,500 birds per hour. It is characterised by a simple design and is easy to install and operate. Its compact design, circular and open layout make it easily accessible for maintenance and cleaning. It can be easily integrated with other systems when needed.

The Carousel cut-up line has a capacity of up to 2,500 birds per hour. It is characterised by a simple design and is easy to install and operate. Its compact design, circular and open layout make it easily accessible for maintenance and cleaning. It can be easily integrated with other systems when needed.

The machine's framework and all the cutting modules for manufactured from stainless steel or other food grade materials. The machine is shipped fully assembled and wired up and comes complete with the control box. It can be operational in around one hour of being placed onto the factory floor.

ADK Carousel Cutter with Conveyors & Batch Weighing

Available at extra cost are many types of conveyors and weighing solutions. The system pictured below includes take away and elevation conveyors for each of the four types of portions cut by the ADK auto cutter.

Each elevating conveyor feeds intelligent batch hopper weighing systems which fills baskets to a pre-programmed weight before turning on a light to indicate that the target weight is reached. Once the target weight is reached, a trap door closes in the scale hopper allowing for portions to be held back until the full basket is replaced with an empty one, and the reset button has been activated.

Similar solutions can be provided for batching only one or more of the portion types.

Portions Produced:

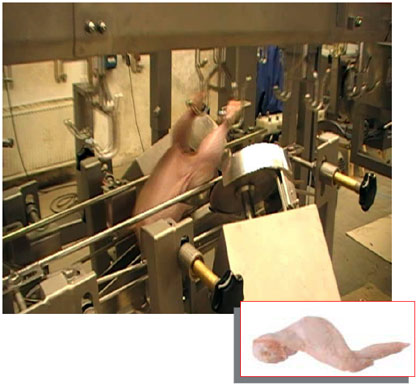

1. Wing stretcher

The wing stretcher module is for positioning and stretching the chickens wings allowing for the correct operation of the wing cutting module. Chickens are transported in the shackle with its breast facing forward. Two steel guides perform the stretching while the birds are moving through the machine. The module is easy to set up and adjustable for different sizes of birds.

The wing stretcher module is for positioning and stretching the chickens wings allowing for the correct operation of the wing cutting module. Chickens are transported in the shackle with its breast facing forward. Two steel guides perform the stretching while the birds are moving through the machine. The module is easy to set up and adjustable for different sizes of birds.

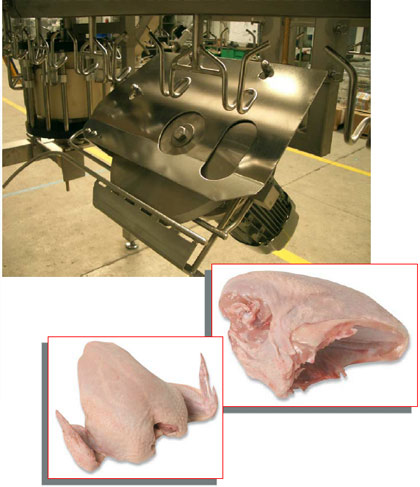

2. Whole wing cutter

The whole wing cutting module consists of left and right cutting units symmetrically positioned in relation to the central line of the shackles. The two rotating blades are mounted on shafts and powered by electric waterproof motors. The chicken carcasses are transported to the module with their backs facing forward and are guided through the machine in a flat-lying position. The wings are caught and correctly positioned between the guides. The wings are cut by the rotating blades.

The whole wing cutting module consists of left and right cutting units symmetrically positioned in relation to the central line of the shackles. The two rotating blades are mounted on shafts and powered by electric waterproof motors. The chicken carcasses are transported to the module with their backs facing forward and are guided through the machine in a flat-lying position. The wings are caught and correctly positioned between the guides. The wings are cut by the rotating blades.

3. Front half (tube) cutter

The front half cutter module removes the front half of the bird with or without wings still attached. This cut is performed by rotating blade with the bird moving sideways through the steel guides. Once cut from the chicken, the front halve is suitable for table top or cone deboning.

The front half cutter module removes the front half of the bird with or without wings still attached. This cut is performed by rotating blade with the bird moving sideways through the steel guides. Once cut from the chicken, the front halve is suitable for table top or cone deboning.

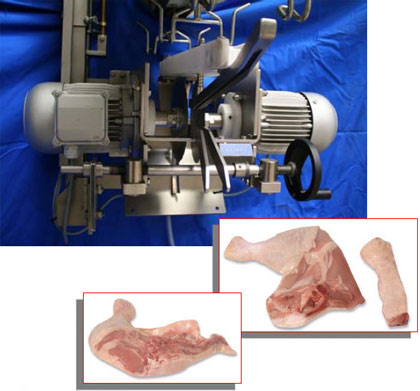

4. Adjustable saddle cutter

The adjustable saddle cutter module is for dividing of the “double legs” into two or three parts. The cut in performed by two cutting blades. These can be adjusted so they are positioned up against each other, so the legs are cut through the backbone. Alternatively, the two blades can be separated so the cut is performed at either side of the backbone. The backbone then falls away. NOTE: The motors are stainless steel and water proof, and are not the same as shown in this picture.

The adjustable saddle cutter module is for dividing of the “double legs” into two or three parts. The cut in performed by two cutting blades. These can be adjusted so they are positioned up against each other, so the legs are cut through the backbone. Alternatively, the two blades can be separated so the cut is performed at either side of the backbone. The backbone then falls away. NOTE: The motors are stainless steel and water proof, and are not the same as shown in this picture.

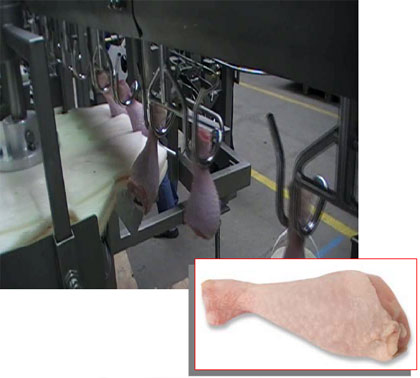

5. Thigh/drumstick cutter

The thigh/drumstick cutter makes an anatomical cut through the joint and splits the thigh from the drumstick. The two legs are precisely positioned by a separating wheel before they are cut. The cut-off thigh falls down while the drumsticks are transported to the next module.

The thigh/drumstick cutter makes an anatomical cut through the joint and splits the thigh from the drumstick. The two legs are precisely positioned by a separating wheel before they are cut. The cut-off thigh falls down while the drumsticks are transported to the next module.

6. Unloader

The unloader is a last module which unloads the remaining drumstick which in turn falls from the machine.